Description

All-in-one battery pouch cell testing station

Modern battery research demands multi-parameter characterization where understanding the relationships between mechanical, thermal, and electrochemical phenomena drives fundamental insights. Advanced material systems—silicon anodes, solid-state electrolytes, lithium-metal configurations, and next-generation thermal interface materials—require correlated analysis that traditional single-parameter approaches cannot provide.

This integrated platform addresses these requirements by providing synchronized measurement infrastructure that eliminates multi-instrument complexity. The system delivers comprehensive, datasets essential for both mechanistic studies and data-driven development methodologies, including machine learning approaches that require high-quality timeseries data with precise parameter correlation.

Applications

Advanced Chemistry Development

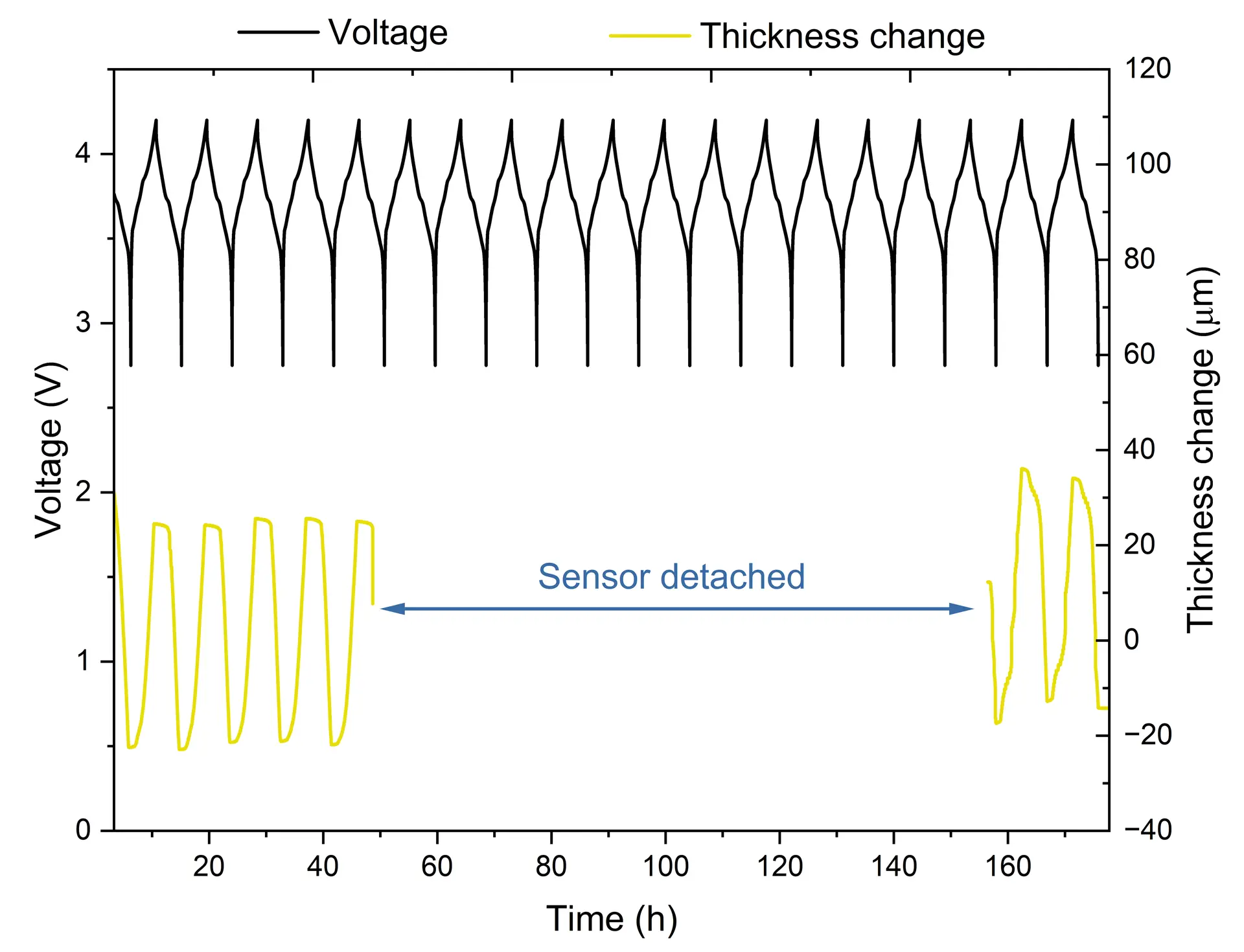

Silicon anodes, solid-state electrolytes, lithium/sodium metal systems. Characterize volumetric expansion dynamics and interfacial pressure evolution.

Formation & Cycling Studies

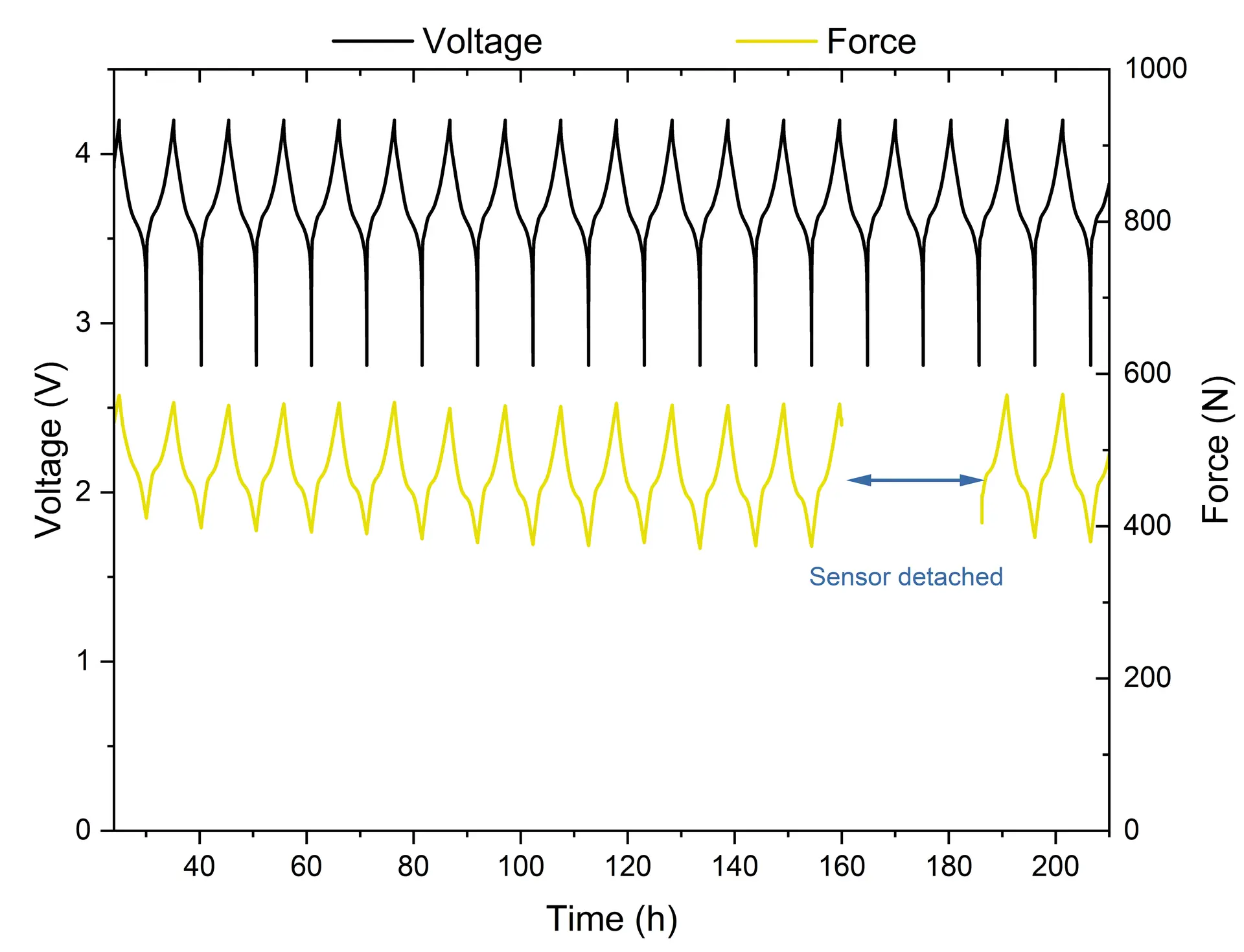

Long-term aging characterization with continuous mechanical-thermal monitoring. Track degradation mechanisms and capacity fade correlations.

Pressure-Dependent Performance

Systematic investigation of electrochemical performance as function of applied stack pressure. Optimize manufacturing constraints

Degradation & Swelling Analysis

Quantify gas evolution, mechanical stress accumulation, and thermal event precursors during accelerated aging protocols.

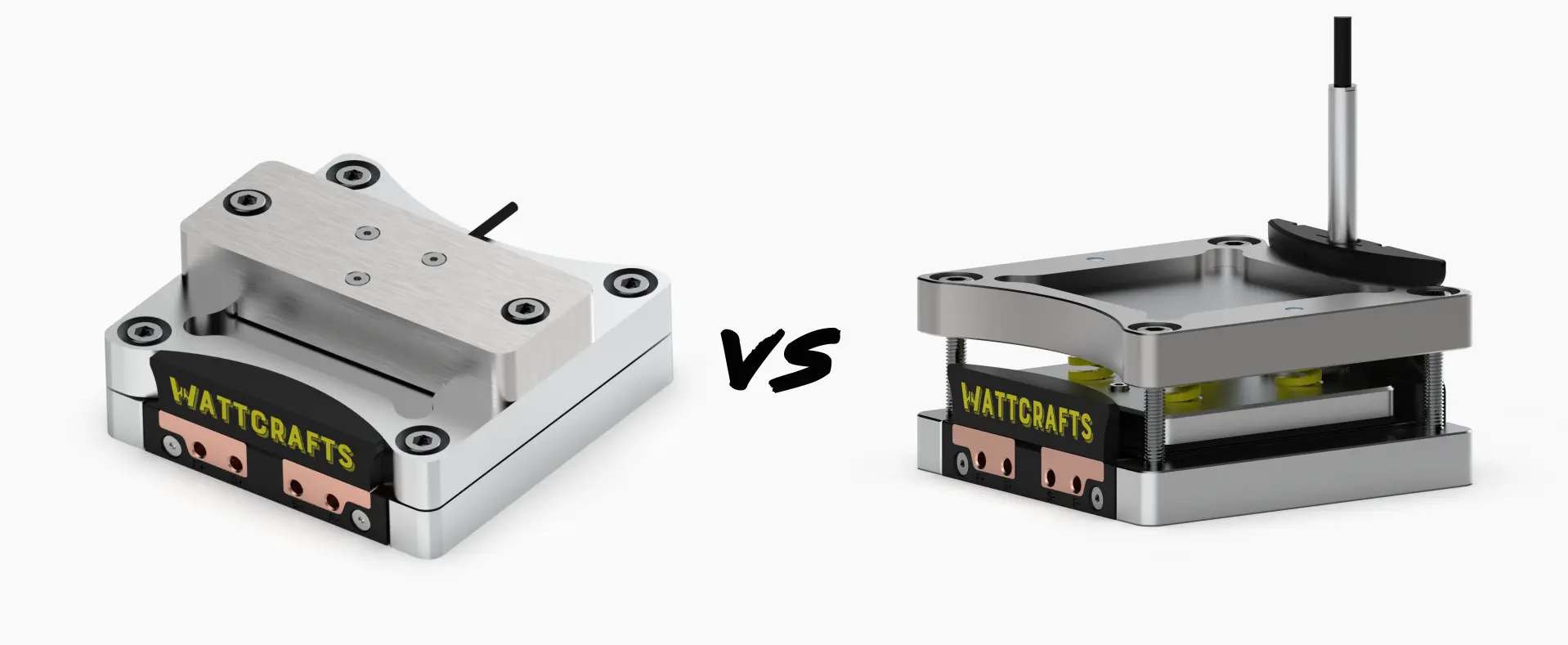

Fixed gap and fixed force modes

This fixture can monitor both force and thickness changes simultaneously during battery cycling. However, the actual response would depend on assembly of holder - either with springs to stabilise pressure, or without springs to prevent cell expansion. Choose setup mode depending on what you want to test.

Fixed gap

Rigid frame — cell thickness fixed, force varies

> Measure pressure build-up & swelling

> Study gas evolution

> Simulate pack conditions with rigid constraints

Fixed force

Spring-loaded — force constant, thickness varies

> Standardized testing conditions

> Investigating volume changes

> Evaluate cycle life under optimal pressure

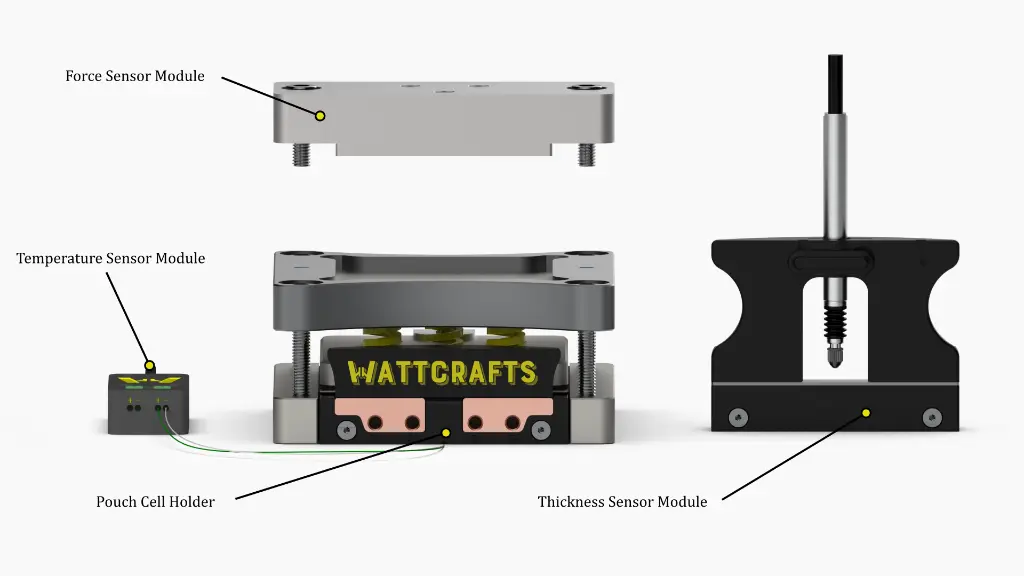

What's included

The platform centers on a precision pouch cell holder that provides mechanical stability and electrical connections. Three sensor modules attach to capture synchronized measurements: force (compression and swelling), thickness (dimensional changes), and temperature. All sensors connect via USB to Omnisense software for coordinated data acquisition and visualization. The modular design enables flexible sensor configurations for different experimental requirements.

Our latest content

Check out what's new in our company !

Extra Accessories Package

- 4-port USB hub

- Leveling tool for easier screws alignment

- Spare flexible pad set

- Calibrated torque wrench

- Omnisense software

- Lifetime support

Omnisense Software

- Synchronized timestamp across all sensors

- Multiple independent measurement channels

- Real-time visualization

- Standard CSV export compatible with Python, MATLAB, Origin, Excel

- Free license included with the platform

Specification

|

Component |

Specification |

|

Pouch Cell Holder |

|

|

Force Sensor Module |

|

|

Thickness Sensor Module |

|

|

Temperature Sensor Module |

|

|

Omnisense Software |

|